The OGM Interactive Edition - Summer 2023 - Read Now!

View Past IssuesImagine a world where renewable energy sources all merge together to power the world. That’s what’s happening now… and that’s the future!

But what does that really mean? How does that really work?

This new energy revolution has a lot of people scratching their heads wondering what the future will look like and how it will all come together.

Think about the world in the past, when we evolved from getting around on horse carriages and then we transitioned to cars. Back then we couldn’t imagine the impact that cars would have on our lives and the world. Cars sparked a game-changing era, which led to other modalities of transport, technology, and innovation. Each one connected to the other to drive progress in new and creative ways.

Just like the cars of yesterday, today we are on the cusp of another game-changing era, the sustainable new energy era.

This era is rising like a tidal wave of opportunities that combine and work together to combat climate change.

Are you ready for the new energy future?

ABB Ltd. is a Swedish-Swiss multinational corporation headquartered in Zürich, Switzerland. The leading technology company was formed in 1988 and has grown to be a global powerhouse in supporting the industry with solutions that address many of the world’s greatest challenges, not least the energy transition and pathway to Net Zero.

In ABB Energy Industries’ Danish office, teams have been working day and night to deliver solutions that will support the growth of new lower-carbon energy models, as well as supporting existing infrastructure to reduce their carbon emissions. It’s a very exciting time.

Martin Bruhn Petersen who is head of sales for ABB Energy Industries in Denmark, specifically has been working on an exciting project that will see ABB implement automation, electrification and digital solutions to the world’s first dynamic green Power-to-Ammonia plant.

Martin says, “The energy transition is complicated for all. Our solutions support building the capacity of the energy mix, adding new innovative and more sustainable fuels to the market. We have found that through early engagement in these markets and individual projects, we help design operations to drive more efficient energy production, whilst simultaneously lowering CAPEX and OPEX. At ABB, we are in a sweet spot of being able to work on leading-edge projects across several new energy markets and are delighted to be supporting the world’s first dynamic green Power-to-Ammonia plant.”

Ammonia is one of the most widely produced chemicals in the world. In its purest form, it is known as Anhydrous Ammonia.

About 80% of the ammonia produced in the industry is used in agriculture as fertilizer. Ammonia is also used as a refrigerant gas, to purify water supplies, and in the manufacture of plastics, explosives, fabrics, pesticides, dyes, and other chemicals. Typically, ammonia has been produced using hydrocarbons as a fuel source.

There are two types of Ammonia: Green Ammonia and Blue Ammonia.

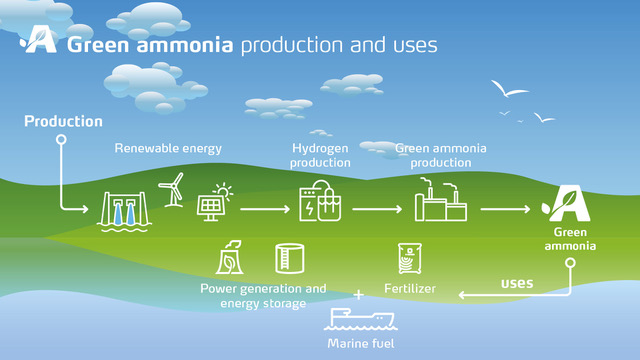

Green Ammonia is produced from hydrogen that is generated using renewable energy sources such as wind, solar, or hydroelectric power. The process of producing green ammonia uses electrolysis to split water into hydrogen and oxygen. The hydrogen is then combined with nitrogen to produce Ammonia.

Blue Ammonia, on the other hand, is produced from hydrogen that is generated using fossil fuels such as natural gas. The process of producing Blue Ammonia uses steam methane reforming to produce hydrogen from natural gas. Blue Ammonia is considered to be a transitional solution that can help reduce greenhouse gas emissions while the world transitions to more sustainable new energy solutions like Green Ammonia.

“Given Ammonia’s high energy volume and the ability to distribute easily across existing infrastructure networks, ammonia has been identified as an alternative fuel for heavy industry and shipping,” explains Martin. It is already used heavily in fertilizers, however, is produced by fossil fuels. By harnessing renewable power as an energy source companies can accelerate the development of this cleaner fuel.”

Governments supporting new energy innovation is key to developing a new energy world.

Government visionaries in Denmark at the Energy Technology Development and Demonstration Programme have allocated approximately $12 Million, to develop the world’s first dynamic green Power-to-Ammonia plant in Lemvig, northwest Denmark.

The revolutionary green Ammonia project is a collaboration between leading and forward-thinking Danish companies: Skovgaard Energy, Vestas, and Topsoe.

The plant will be a demonstration facility, which means that it will be used to test and refine the technology before it is scaled up for commercial use. The Plant is expected to produce 5,000 tons of ammonia a year.

ABB has been brought on board to support the development of this exciting project. Being a green Power-To-Ammonia project, the plant will use renewable energy from wind turbines and solar panels to produce green ammonia, which can be used as a fertilizer or as a fuel for transportation.

The demonstration facility, scheduled to start operating in 2024, is a Power-to-X (PtX) plant and will be powered by renewables from existing 12 MW wind turbines and new 50 MW solar panels.

ABB will be responsible for electrical integration and advanced process control of the full Power to Ammonia plant operating in a highly dynamic mode – which means enabling production to adjust based on the availability of renewable energy. This makes it a highly efficient and sustainable solution for producing green ammonia.

The plant will be able to operate when the sun shines and the wind blows but can also gear production down when neither renewable energy source is present. Being able to adapt to fluctuations in energy makes it different from other types of PtX plants, which are directly connected to the grid.

“Enabling PtX plants to run optimally and connecting them to the grid is a complex job. To operate 24/7 they need enough energy constantly available even when there is not sufficient renewable energy from the sun and wind,” said Martin. “Equally when integrating them to the grid we must avoid disruptions when there are fluctuations in energy production or if consumption outweighs demand. This is where dynamic plants such as this one, which can power down when there is no energy supply available, are invaluable and will play a key role in increasing grid capacity without compromising stability.”

ABB solutions will deliver full visibility of production, maximizing efficiency and ensuring optimal energy use. This Power-to-Ammonia project is a significant step towards a more sustainable and environmentally friendly future. Reaching net-zero goals and solving climate change issues will happen because of the great minds that develop projects like this, the world over.

Did you enjoy this article?