The OGM Interactive Edition - Summer 2023 - Read Now!

View Past IssuesThe Net Zero Project is a collaboration within the energy and environmental industries to drive economic growth, diversification, investment, and awareness through the lens of sustainability and the pursuit of net zero in Newfoundland and Labrador’s energy sector.

The Net Zero Project supports the development of clean growth strategies and projects in priority areas of Canada’s net zero journey as they relate to its offshore energy industry: carbon capture, utilization, and storage; electrification and renewable energy; and hydrogen.

The Net Zero initiative includes a range of activities, such as:

Aker Solutions is a market leader in both offshore greenfield and offshore brownfield electrification of oil

and gas facilities through studies and projects in Norway, Scotland, Gulf of Mexico, Australia and Brazil.

Aker has taken the learnings from these activities and applied them to potential developments offshore

Newfoundland and Labrador.

Offshore platforms typically generate electricity by burning fossil fuels to run onboard gas turbines and/or

diesel-powered generating units. An alternative is to supply offshore installations with electricity from the

mainland using a power cable transmission system.

There are many benefits to utilizing power from the shore including reduced CO2 emissions, increased efficiency due to increased uptime of power system, increased safety due to reduction in possible sources of ignition and reduced planned maintenance and lower operating costs.

Power can be connected from shore via alternating current (AC) or direct current (DC). For distances longer than 150 km, high voltage direct current (HVDC) has historically been used. The power transmission losses of the entire string do however always need to be considered from an overall perspective.

Power from shore is widely used offshore Norway where sixteen fields constituting 45% of the countries’ oil and gas production will be connected to the shore by 2023 by both HVDC and AC cables. Similar to

Newfoundland and Labrador, Norway’s electrical grid is predominantly powered by low GHG emitting

hydroelectric power. This project aims to apply lessons learned from the Norwegian power from shore

experience to future developments in the more challenging offshore environment of Newfoundland and

Labrador.

Offshore developments in Norway are typically in 100-400m water depth, and generally within 150km of

shore, whereas the potential development areas identified in this scope are in iceberg-prone locations more than 400km offshore and in water depths greater than 1200m. This water depth leads to floating solutions that have to be readily able to disconnect in the event of a potential iceberg impact. The only FPSO currently powered from shore in Norway is the permanently moored circular Goliat FPSO located in 400m of water and 100km offshore, in an area that is not prone to icebergs.

Two potential greenfield power from shore development scenarios have been identified; a development in the West Orphan Basin with a point of interconnection (POI) at the Soldiers Pond station, and a potential development in the Labrador Sea with a POI at the Muskrat Falls generating station (See Figure 3-1: Potential Power From Shore Development Areas).

Aker’s analysis indicates that electrifying new floating developments in these locations is challenging but feasible. These developments would be amongst the furthest from shore and deepest water electrification projects carried out to date.

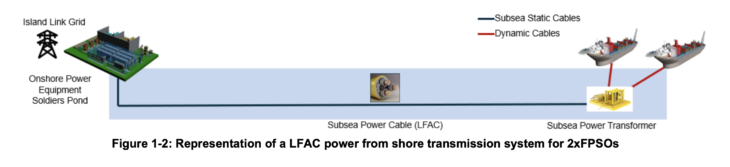

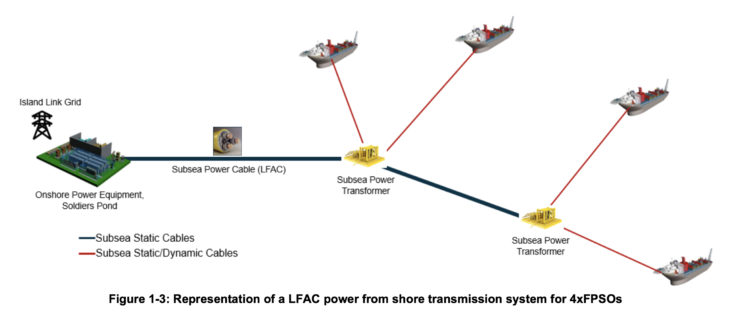

The most appropriate technology for these locations is low-frequency AC distribution with subsea transformers acting as distribution points to the FPSO. The diagrams below are a representation of the preferred LFAC approaches.

The development of this initiative points toward the use of a Low-Frequency AC transmission and distribution system. This transmission technology will require less onboard space, reduced weight, and offer more flexibility in the electrical system design of the FPSO because major equipment, such as a gas compressor, can utilize the incoming 20Hz power and smaller converters and transformers can feed the remaining equipment as necessary.

This will lead to reductions in regular maintenance, and increases in system uptime as the system does not require the maintenance or downtime associated with main power generation by onboard rotating machines.

This system would require an onshore connection to the power grid and equipment to step down the voltage between 132kV and 145kV for subsea transmission. It also requires a subsea cable connected to a subsea transformer for distribution to multiple FPSOs, and to step down the power from the transmission voltage to 50-66kV, for use on each FPSO. It would also require dynamic cables from the sea bed to the FPSO, and will require the use of an electrical swivel if a ship-shaped FPSO concept is selected.

Did you enjoy this article?