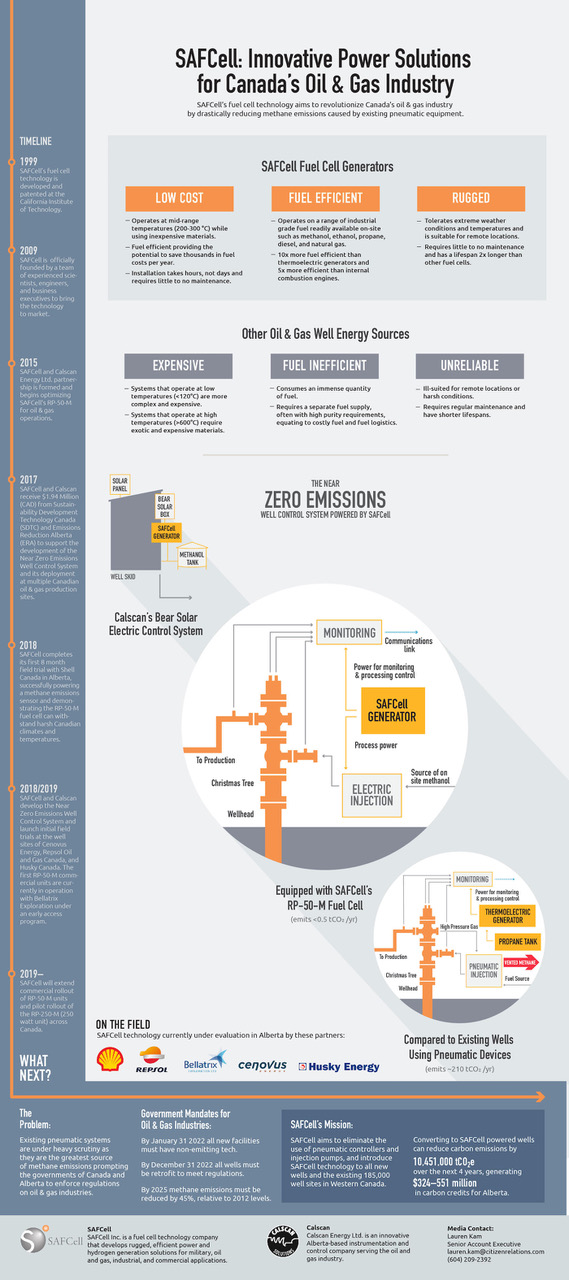

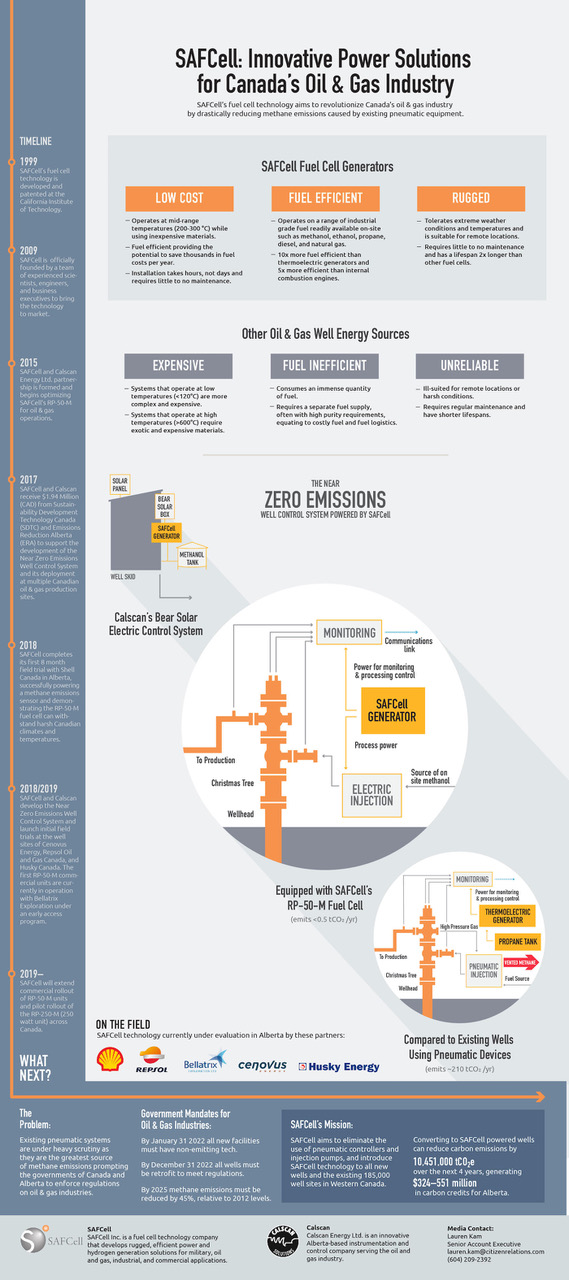

SAFCell Teams up to Develop a Near Zero Emissions Well Control System

Canada’s climate has been warming at roughly twice the rate of the rest of the world, according to a report on Canada’s Changing Climate released on April 3rd. In light of this, Canada’s oil and gas industry is focused on transforming its operations as it continues to receive heavy regulatory scrutiny over methane emitting pneumatic equipment used at well sites.

Funded by a $1.94 million grant from Sustainable Development Technology Canada and Emissions Reduction Alberta, SAFCell, an innovative fuel cell company, has teamed up with Alberta-based Calscan Energy to develop a Near Zero Emissions Well Control System that is fuel flexible, inexpensive, and durable, with the capability to drastically reduce methane emissions caused by existing well sites.

In light of the recent mandate imposed by the governments of Canada and Alberta to reduce methane emissions by 45% by 2025 (relative to 2012), oil and gas industries are looking for new, innovative ways to reduce their carbon footprint. As Canada prioritizes policy changes for a more sustainable future, SAFCell anticipates a growing demand for its technology having successfully deployed multiple fuel cell units with Canadian O&G partners, including Shell Canada, Husky Energy, and others. Converting Western Canada’s 185,000 well sites to SAFCell power has the potential to reduce carbon emissions by 10,451,000 tCO2 each year, the equivalent annual GHG emissions of approximately 2,218,896 passenger vehicles!

About SAFCell

What is SAFCell?

- Founded in 2009 with proprietary technology from the California Institute of Technology, SAFCell

develops transformative Solid Acid Fuel Cells for stationary and portable power applications in the oil

& gas, military, industrial, and commercial sectors.

- SAFCell’s remote power products are rugged, reliable, and fuel flexible, operating on existing

commercially available fuels including methanol, ethanol, propane, diesel, and natural gas resulting in

lower operating and maintenance costs.

RP-50-M Power System

- SAFCell’s RP-50-M remote area power system (50-watt unit) is a low-cost, fuel efficient, and

dependable energy solution for the oil & gas industry and outperforms alternative solutions with

respect to installation and operating costs.

- Applications in the oil & gas industry include SCADA, electronic control and injection systems, and

other systems requiring reliable off-grid power.

- SAFCell has launched its RP-50-M power system in Canada with install partner Calscan Energy and oil

& gas operators Shell Canada, Husky Energy, Repsol Oil and Gas Canada, Cenovus Energy, and Bellatrix

Exploration.

RP-50-M Advantage for Canadian Oil & Gas

- Fuel-Flexible: Operates on readily-available onsite field-grade methanol minimizing the need for

additional fuel and delivery costs.

- Fuel Efficient: 10x more efficient than thermoelectric generators and 5x more efficient than internal

combustion engine generators which save thousands of dollars per year in operating costs while

reducing CO2 emissions.

- Reliable: Rugged military design built for demanding oil & gas field conditions and extreme

temperatures of Canadian winters and summers; can be transported and deployed quickly with little

to no maintenance required.

Calscan Energy and SAFCell Partnership

- Founded in 1995, Calscan is a leading instrumentation and control company based in Edmonton,

Alberta.

- Calscan created the Bear Solar Electric Control System for the electrification of new and existing well

sites to significantly reduce GHG (methane) emissions. These durable systems have been deployed at

over 350 well sites in Canada.

- SAFCell and Calscan have now partnered together to develop a Near Zero Emissions Well Control

System (NZE WCS) to eliminate methane emissions from oil & gas production facilities in Canada.

Near Zero Emissions Well Control System and Emissions Reduction Potential

- The NZE WCS combines SAFCell’s RP-50-M methanol fuel cell with Calscan’s solar/battery powered

Bear Control System to create a reliable, efficient, and rugged power source for well sites.

- The system offers a clean alternative to standard pneumatic equipment that is currently the greatest

source of methane emission from the oil & gas industry and under heavy regulatory scrutiny in Canada.

- The current deployment initiative is funded by a $1.94 million (CAD) grant from Sustainable

Development Technology Canada (SDTC) and Emissions Reduction Alberta (ERA) to address the

mandate from the governments of Canada and Alberta to reduce methane emissions by 40-45 per

cent by 2025 (relative to 2012 levels).

- SAFCell powered systems can generate $324-551 million in carbon credits for Alberta over the next

four years.

SAFCell and Calscan Field Trials in Canada

- Near Zero Emissions Well Control Systems have been deployed at multiple Canadian oil & gas sites

operated by 11 partner companies including Shell Canada, Cenovus Energy, Repsol Oil and Gas

Canada, and Husky Energy.

- In 2018, a successful eight-month trial was completed at the Shell Canada Rocky Mountain House well

site in Alberta deploying multiple RP-50-M units and demonstrating operability in the field at both low

and high temperatures.

- In the winter of 2018/2019, trials were extended to Cenovus Energy, Repsol Oil and Gas Canada, and

Husky Energy. The first RP-50-M commercial units were deployed with Bellatrix Exploration under a

SAFCell early access program and are currently in operation.

- SAFCell will be extending the commercial rollout of the RP-50-M and pilot rollout of the RP-250-M

(250-watt unit) across Canada, starting with 185,000 well sites in Western Canada.

Did you enjoy this article?