by TheOGM

Published on August 23rd, 2012

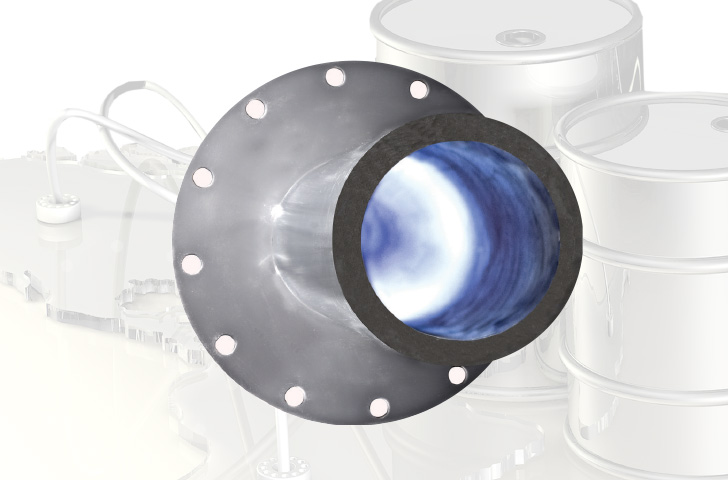

The Cleanest Burner in the Alberta Oil Sands

Absolute Combustion International Inc. (ACI) is in the final process of testing and receiving industry standard approvals for a revolutionary low-emission combustion burner system. Absolute Combustion’s burner technology not only aims to increase the energy efficiency of process heating, but also to drastically reduce the emissions of multiple harmful pollutants including NOx and C0 gases.

Absolute Combustion has reported an incredible NOx emission reduction performance of 16-19PPM, single pass, without the need to re-circulate flue gas. They have also reported zero C0 emissions in their exhaust gas, which is achieved by the Absolute Extreme BurnerTM combustion efficiency of 99.9 percent or greater.

This may not sound like much, but in reality a dramatic boost in combustion efficiency, along with a major reduction of NOx emissions, show that an unmistakable breakthrough has occurred.

Nearly two-thirds of global energy consumption is accounted for by the combustion of hydrocarbon and fossil fuels in burners, boilers, and turbines. These systems are used to provide heat for all manners of industrial processes and for building heat.

“67 percent of global energy is used in combustion. When fossil fuels burn, they produce exhaust gases. In addition to carbon dioxide, which contributes to the greenhouse effect, there are smaller amounts of poisonous carbon monoxide (C0), various nitrogen oxides (NOx), and other airborne pollutants.”

In order to keep pace with increasing regulatory guidelines for emissions, heavy oil and gas producers are under major pressure to reduce their air pollution emissions.

Fred Shaw, former partner (P. Eng) of Colt Engineering, explains the Absolute Combustion innovation as it relates to his business, “Absolute Combustion has invented and developed a burner technology that, when applied to most applications that require heat, such as treaters, separators, plastic extruders, kilns, boilers, etc., will increase energy efficiency, lower emissions and reduce the amount of fuel consumed during normal operation by 10 to 15 percent or more.”

The first practical applications, for the burner technology ACI is implementing, are in heavy oil production for separators and treaters, line heaters, and SAGD.

Perfect Burn Environment

While most current burner technology designs rely on blowing heated or re-circulated air over the point of combustion, Absolute Extreme Burner™ technology uses forced air and/or

compressed air, injected into their proprietary burner design at the exact point of combustion, to help create a near-perfect burn environment.

By injecting forced air or compressed air at the exact point of combustion, the air to fuel mixture can be controlled and adjusted, ensuring an optimal mixture, thereby creating the most efficient burn with minimal emission production.

Absolute Combustion Burner Technology Is Not Impacted by Atmospheric Conditions

The greatest benefit of their new burner technology is that it is minimally impacted by atmospheric conditions such as elevation, barometric pressure, and temperature; therefore, it can be used in existing industrial applications such as lineheaters (3 MMBTU or larger), separators, treaters, boilers, processors, dehydrators, industrial furnaces, kilns, etc. The Absolute Extreme Burner’s™ ability to directly affect fuel consumption through its high level of efficiency helps to reduce the amount of fuel needed to produce the same outputs as competitive burners. It is anticipated that the Absolute Extreme Burner™ technology will help businesses reduce their fuel consumption without sacrificing efficiency.

Minimal Flame Impingement in Fire Tube Applications

The Absolute Extreme Burner™ generates an unprecedented thermal and heat transfer efficiency without the requirement of high fuel pressures. At the same time, it creates a near flameless burn, thereby reducing the ongoing concern regarding flame scorching, flame impingement, or flame by-product build-up.

Workplace Safety

The Absolute Extreme Burner™ utilizes low fuel pressure in order to significantly increase workplace safety. When something goes wrong in a high fuel pressure environment, the challenge can become catastrophic. In a low-pressure environment, the danger levels drop significantly.

The key measurements in Environmental Stewardship as reported by CAPP in the 2010 Responsible Canadian Energy Data include: 1. Air Emissions: NOx, GHG, C02 2. People: Workplace Safety.

Absolute Combustion is one of the “sustainable” companies that help heavy oil and gas producers achieve significant performance improvements: environmental sustainability, workplace safety, and economic viability.

Absolute Combustion firmly believes that we must all take immediate steps to protect the land, the air, and the water we use with reckless abandon, in order to ensure future generations will inherit a healthy planet.

Get in touch:

DARSELL KARRINGTON, PRESIDENT & CEO ABSOLUTE

COMBUSTION INTERNATIONAL INC.

OFFICE: 403.277.2297

EMAIL: darsell@absolutecombustion.com

www.absolutecombustion.com

Did you enjoy this article?

Marine Energy - Producing Electricity from Low Velocity Currents

Marine Energy - Producing Electricity from Low Velocity Currents What Does Google Have to do with Energy?

What Does Google Have to do with Energy? Turning Waste Plastic into Crude Oil in Midst of Our New-Energy Era

Turning Waste Plastic into Crude Oil in Midst of Our New-Energy Era ISEEESA: Safety and Sustainability

ISEEESA: Safety and Sustainability The Global 100 Most Sustainable Corporations in the World

The Global 100 Most Sustainable Corporations in the World