by Melissa Parsons

Published on February 23rd, 2012

Turning Waste Plastic into Crude Oil in Midst of Our New-Energy Era

The Agilyx mission is to provide the world with an environmentally beneficial source of crude oil by partnering with waste generators and aggregators to economically handle difficult-to-recycle waste plastics. - Interview with Chris Ulum, Agilyx CEO

The OGM: Where did the idea to start Agilyx come from?

Chris Ulum: For over a decade, Agilyx Founder and CTO Kevin DeWhitt researched and investigated a process to generate a usable product from difficult- to-recycle plastics that have become a huge problem for our waste streams and landfills. Initially the product was diesel fuel, but because of the technical complexity and risk, Mr. DeWhitt’s efforts were refocused on the production of synthetic crude oil, which would be clean enough to market and sell. Agilyx was then created in 2004, and the technology was further developed and became relatively simple in scope. Agilyx currently produces an oil product that any commercial-scale refinery could accept and refine into a myriad of products and petrochemicals that are in use today.

The OGM: Can you tell me about your technology? (How was it developed? Discuss the benefits and how it works)

Chris Ulum: Agilyx is the first company to economically convert difficult-to-recycle waste plastic into synthetic crude oil, using a process that is scalable, versatile and commercially viable. The company designs, manufactures, and sells systems to industrial- waste- plastic recyclers and municipal aggregators.

Agilyx uses a patented, fully permitted process that converts ground waste plastic into synthetic crude oil. The Agilyx base system consists of four primary vessels and the associated secondary processing equipment. This base system is capable of converting approximately 10 tons of plastic into approximately 55 barrels of oil per day.

The Agilyx technology provides for the ability to scale the processing capacity to meet a customer’s requirements in increments of 10 tons per day by combining multiple base systems together. One common exhaust system manages the hot air produced by all of the processing units, while one state-of-the-art environmental control device scrubs all of the noncondensable gases, ensuring that the system meets the most stringent air-quality requirements. The innovative Supervisory Station, with touch screens and graphical user interface, allows operators to monitor and manage all parts of the system from one central location.

The OGM: What are the benefits to the environment when the Agilyx technology is used?

Chris Ulum: Using Agilyx technology will divert difficult to recycle waste plastics (mostly numbers 3-7, but Agilyx can take all types) from garbage streams, complementing recycling efforts, extending landfill life and preventing the need for incineration, while providing a cost-effective end-of-life solution for waste plastic to help create cleaner and more empowered communities.

The OGM: What kinds of petroleum products are produced by Agilyx technology?

Chris Ulum: Agilyx technology produces ultra-sweet synthetic crude oil. Like traditional crude oil, it can be refined into a number of products, including plastics, fuels and other petrochemical products. Synthetic crude oil is often lower in impurities than traditional crude, potentially making it easier for refiners to upgrade the product.

The OGM: On your website, a Key Fact is listed: A 50 percent projected increase in global demand for oilin the next 20 years—How will that affect Agilyx?

Chris Ulum: Although many would love to just say “no” to oil, that isn’t the world we live in today. This means we and other innovators around the world need to look at more positive, alternative ways to satisfy this growing demand until we can achieve an oil-free future.

Did you enjoy this article?

What Does Google Have to do with Energy?

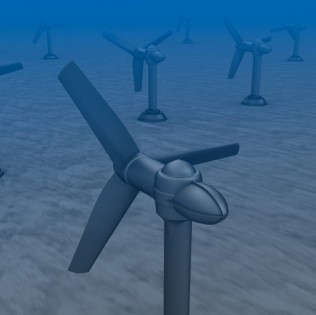

What Does Google Have to do with Energy? Marine Energy - Producing Electricity from Low Velocity Currents

Marine Energy - Producing Electricity from Low Velocity Currents Alberta’s Clean Energy Story

Alberta’s Clean Energy Story Sustainable Energy - Dawson Creek Leads the Way for Canada

Sustainable Energy - Dawson Creek Leads the Way for Canada Sustainable Energy Initiatives - Electricity Sector

Sustainable Energy Initiatives - Electricity Sector