The OGM Interactive Edition - Summer 2023 - Read Now!

View Past IssuesThe sustainable eFuels industry is a rapidly growing sector that produces synthetic fuels from renewable energy sources. eFuels are synthetic fuels that have the potential to be nearly carbon-neutral and are made from carbon dioxide (CO2) and hydrogen using renewable energy sources such as wind, solar, and nuclear power. They can be produced via a virtually CO2-neutral process, which means that they can help to rapidly reduce carbon emissions.

The potential of eFuels to decarbonize aviation and maritime shipping is significant, and there are ongoing efforts to accelerate their adoption through targeted policies, such as introducing carbon pricing for shipping and aviation, scaling up the production of low-carbon e-fuel, and regulating the lifecycle emissions intensity of e-fuels.

eFuels, also known as electro fuels, are a class of synthetic fuels that can replace conventionally produced fossil fuels. eFuels combine green hydrogen and carbon dioxide (CO2) to produce eMethanol, which can then be converted to a wide range of sustainable fuels, including eSAF, eGasoline, and eDiesel.

Sustainable aviation fuel (SAF) is a type of aviation fuel that is made from sustainable resources such as renewable or waste-derived sources. It is a “drop-in” fuel that can be mixed with any fossil jet fuel to reduce emissions.

SAF meets sustainability criteria and has the potential to reduce the carbon footprint of the aviation industry. SAF can be made from renewable sources such as used cooking oil, municipal waste, and woody biomass.

It is a safe and proven fuel that has the potential to reduce the carbon footprint of the aviation industry. SAF is a carbon-reduction solution that is available for use in aircraft and helicopters operating today. It is estimated that SAF could contribute around 65% of the reduction in emissions needed by aviation to reach net zero in 2050.

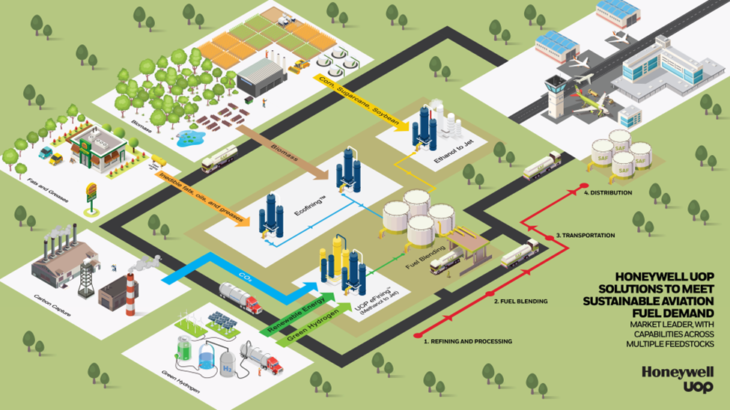

Leigh Abrams is the Senior Business Leader for Emerging Renewable Fuels in the Sustainable Technology Solutions business at Honeywell UOP and is responsible for UOP’s technologies to produce renewable liquid fuels from next-generation feedstocks. The UOP renewable fuels portfolio includes EcofiningTM, UOP eFiningTM and the UOP ethanol to jet process, as well as technology for biomass conversion into liquid fuels.

Leigh explains, “Honeywell UOP eFining Technology is a groundbreaking technology that converts waste oils, fats, and greases into Honeywell Green Jet Fuel, a drop-in replacement for jet fuel. This technology, which can produce eSAF at a lower cost relative to comparable technologies, is efficient and can reduce greenhouse gas (GHG) emissions by 88% compared to conventional jet fuel1. The technology is safe because it produces aviation fuel that meets the same specifications as traditional jet fuel.”

Honeywell’s UOP eFining is a methanol to jet fuel (MTJ) processing technology that can convert eMethanol to eSAF reliably and at scale. When blended with conventional jet fuel, eSAF is a drop-in replacement fuel that requires no changes to aircraft technology or fuel infrastructure.

The safety of sustainable aviation fuels (SAF) is regulated by various organizations and agencies.

All jet fuel that is shipped carries a Certificate of Quality showing compliance with ASTM D1655, which is a standard specification for aviation turbine fuels. The FAA Part 139 addresses fire safety standards for fuelling operations, and fuel quality control is inspected by the FAA Flight Standards Division Inspectors.

The International Civil Aviation Organization (ICAO) also regulates the safety of aviation fuels, including SAF. The ICAO has developed standards and recommended practices for the production, handling, and use of aviation fuels, including SAF.

The U.S. Department of Energy Bioenergy Technologies Office (BETO) supports advances in research, development, and demonstration to overcome barriers to the widespread deployment of low-carbon SAF that meets strict fuel specifications for use in existing airplanes and infrastructure. The safety of SAF is a critical aspect of the aviation industry, and various organizations and agencies work together to ensure that SAF is safe and reliable.

The UOP eFining technology is highly integrated and can process flexible feedstocks using commercially proven processes, resulting in operational reliability, minimized capital expenditures, and low energy intensity. This technology is a transformational opportunity for the aviation market, allowing for the use of readily abundant CO2 to produce SAF.

HIF Global is the world’s leading eFuels company and has signed a commercial agreement for the production of eSAF using Honeywell UOP eFining. HIF expects to deploy the solution at its second commercial-scale eFuels facility in the U.S., which is expected to be the world’s largest eSAF facility, recycling approximately 2 million tons of captured CO2 to make approximately 11,000 barrels per day of eSAF by 2030.

The demand for SAF continues to grow, and various incentives, including the Sustainable Aviation Fuel Grand Challenge and ReFuelEU Aviation rules, have been introduced to accelerate the commercialization of technologies like Honeywell UOP eFining to meet the growing demand for SAF. These incentives aim to increase the share of sustainable fuels at EU airports from a minimum of 2% in 2025 to 70% by 2050, with an additional sub-target for eSAF of 1.2% by 2030 and 35% in 2050.

Reduced GHG emissions are based on UOP carbon intensity analysis, derived from a 3rd-party study of methanol production from green hydrogen and CO2 captured from biomass processing, in comparison to fossil fuels.

Did you enjoy this article?