The OGM Interactive Edition - Summer 2023 - Read Now!

View Past IssuesJanuary 30, 2023

Atlas Salt is pleased to announce the results of an independent Preliminary Economic Assessment and updated Mineral Resource estimate prepared by SLR Consulting (Canada) Ltd. on its 100%-owned Great Atlantic Salt Project located on the west coast of Newfoundland. Great Atlantic is the premier undeveloped salt deposit situated in the heart of a large regional U.S./Canadian road salt market facing a significant domestic production shortfall.

Mr. Rowland Howe, Atlas President, commented: “In my 30+ years in this industry I have not come across a salt project as unique as Great Atlantic given its combination of size, shallowness, and logistical advantages. This robust PEA confirms our vision for the project.”

Mr. Howe added, “Even assuming a conservative flat production rate at 2.5 million tonnes over only 30 years, the cash flow model provides a base case evaluation that is quite compelling. Significant additional value can be attributed to the project given that mine infrastructure is designed for up to 4 million tonnes of production with ample resources to extend production beyond 30 years. Future additional infrastructure could push annual production even higher. Long life cash flow comes at a premium.”

The PEA considers developing Great Atlantic into an underground operating mine capable of producing 2.5 Mtpa of rock salt with key mine access and plant infrastructure designed for 4.0 Mtpa. Construction of the mine would occur over three years, with access to the deposit via twin declines. Extraction of rock salt would occur using the room and pillar method, with continuous mining equipment. Salt would be processed to a specific size and grade using a crushing and screening plant located within the mine, and then brought to the surface via conveyor belts. An overland conveyor would transport the rock salt from the mine area to the existing Turf Point port for loading onto ships destined for Canadian and American markets, as well as serve the local Newfoundland market. The PEA is a step towards a Feasibility Study which is currently underway by SLR.

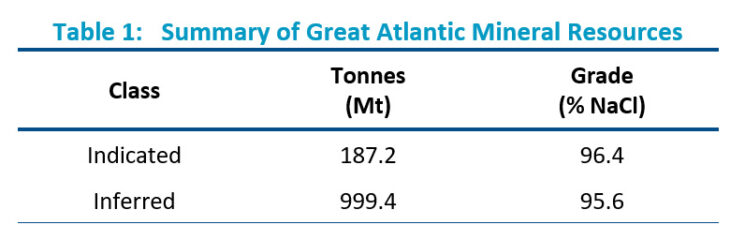

Canadian Institute of Mining, Metallurgy and Petroleum (CIM) Definition Standards for Mineral Resources and Mineral Reserves (CIM (2014) definitions) were used for Mineral Resource classification. The updated Mineral Resource currently includes 187.2 Mt of Indicated material plus 999.4 Mt of Inferred material. Table 1 provides a summary of the Great Atlantic Mineral Resource estimate prepared by SLR, with an effective date of January 6, 2023. The Mineral Resource estimate does not incorporate information from hole CC-9, with salt analysis pending, announced in an Atlas Salt news release dated January 11, 2023.

Mining designs, development plans, and schedules have been prepared for a fully electric, mechanized room and pillar mining operation. Salt will be mined using continuous miners and hauled by truck to a lump breaker and conveyor system to move material to a crushing and screening plant located underground. The PEA is based upon the initial production of 2.5 Mtpa of rock salt product with mine infrastructure capacity to expand to 4.0 Mtpa.

The mining designs contained in the PEA are based, in part, on Inferred Mineral Resources. Approximately 39% of the mine plan is based on Indicated Mineral Resources, with the remainder being Inferred Mineral Resources. Inferred Mineral Resources are considered too geologically speculative to have economic considerations applied to them that would enable them to be categorized as Mineral Reserves. There is no certainty that the production forecasts on which the PEA is based will be realized.

The mine will be accessed through two declines driven to 250 m below the surface where the plant and related infrastructure will be located. One decline will provide fresh air into the mine and be used for vehicle access, while the other will exhaust air and contain an overhead conveyor to transport finished rock salt product to the surface. Twin declines will be extended from the 250 Plant Level to the first production level at 300 m below the surface, continuing to the lower levels as required. The primary mine-related infrastructure including maintenance shops, vehicle charging bays, and gear storage will be located on the 300 Level.

Internal declines will be developed as necessary to sustain the initial production rate of 2.5 Mtpa over an initial 30-year mine life. A total of six production levels supported with six internal declines and level-specific infrastructure will be constructed to support mining activities on each level. Room and pillar production mining will be executed in four cuts of five meters in height, resulting in a maximum room height of 20 m. Rooms will be 16 m wide, separated by 25 m square pillars. The square pillars will be in a regular pattern and overlie one another from level to level. Each mining level will be separated by 20 m thick horizontal sill pillars.

Al major equipment used in the mine will be battery electric or plugged electric, with minimal diesel-powered equipment in the mine.

Processing of the salt will take place at a crushing and screening plant located within the mine. The rock salt produced will be suitable for use as a deicing product, conforming to specification ASTM-D632, with a minimum NaCl grade of 95%. There are no chemical processes or reagents involved in the production of rock salt, other than an anti-caking agent that is added to the product immediately before shipping. After rock salt has been processed, it will be transported to the surface via conveyor belts. On the surface, a series of conveyor belts will transport the rock salt from the mine site to the port.

The Great Atlantic operation will include both on and off-site infrastructure. On-site infrastructure has been configured to minimize the mine site surface footprint. Components of the on-site infrastructure include:

Notably, a tailings management facility is not required for the Project, as all material that is processed will be sold as rock salt.

Off-site infrastructure has been designed to take advantage of some of the existing facilities available in the immediate area, including the port, historical haul road, and an NL Power electrical substation. Planned off-site infrastructure includes the following:

Environmental baseline studies of the project area have been completed by GEMTEC Consulting Engineers and Scientists Limited (GEMTEC) throughout 2022 in preparation for the registration of the project under the environmental review process. Consultations with the local community and affected groups are ongoing. Atlas has retained the services of an experienced communications consultant to assist and facilitate informed community input into the project development.

As part of the PEA and ongoing Feasibility Study, Atlas and SLR have commissioned independent assessments of marketing and logistics. These independent assessments have formed the basis of the assumptions used in the PEA.

Rock salt produced from Great Atlantic will initially target the regional deicing markets in eastern Canada and the U.S. East Coast. It is estimated that this market requires between 11.0 Mtpa and 16.0 Mtpa of rock salt in any given year, sourced from domestic and international suppliers, with the demand highly correlated to weather conditions. The primary customers of rock salt are government entities that use a tender system for the annual supply of deicing salt. Secondary customers include commercial deicing operators.

Government entities include municipalities, Departments of Transportation (DoT), counties, and other provincial or state entities, while commercial operators may vary from distribution companies for retail purchases or contractors who purchase rock salt for de-icing commercial and private properties.

SLR has prepared a cash flow model that is based on a 30-year mine plan with a production rate of 2.5 Mtpa. It is noted that the Mineral Resource base will allow for a much longer mine life. The mine schedule includes a three-year ramp-up period, with year one production of 1.5 Mtpa, year two production of 2.0 Mtpa, and year three reaching steady-state production of 2.5 Mtpa.

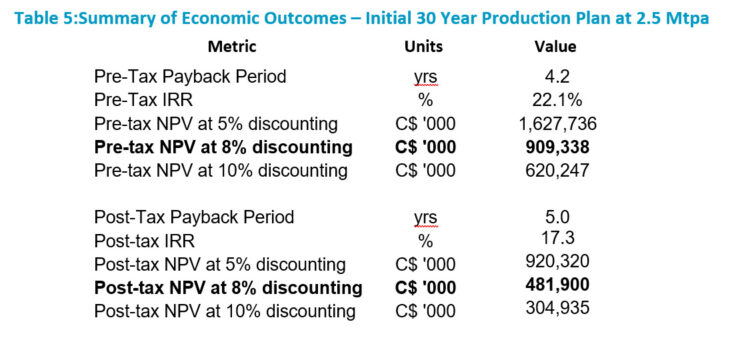

The cash flow model comprises estimates of capital costs, operating costs, an assessment of revenue, and an estimate of project economic metrics such as net present value, internal rate of return, and payback period. Economic metrics were assessed both on a pre and post-tax basis.

SLR has assumed that construction of the mine would commence in 2025, with salt production commencing in 2028. To bring salt prices to a 2028 base date, SLR has applied a 4.0% annual increase to the price of salt, which is consistent with other publicly available technical reports on existing salt operations in North America. Beyond 2028, SLR has applied a 2.0% annual increase to the price of salt. In terms of costs, SLR has applied 2.0% annual inflation to capital and operating costs.

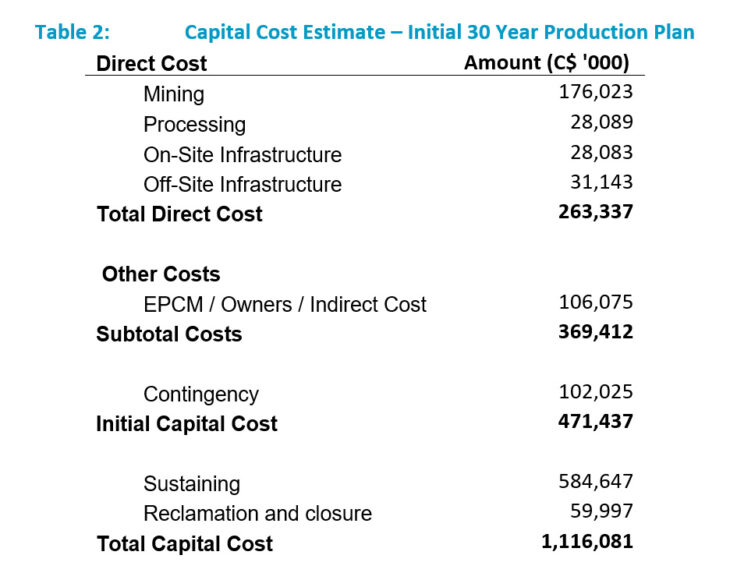

Capital costs for the Project have been estimated based on first principles build-ups, factored estimates, and quotes for major equipment and supplies. The capital cost estimate conforms to an AACE Class 5 estimate, as of the fourth quarter of 2022. Capital costs are divided between pre-production capital (representing years leading up to salt production) and sustaining capital. Costs are divided into areas including mining, processing, infrastructure, off-site infrastructure, indirect costs, owner’s costs, and contingency. The capital cost estimate is presented in Table 2.

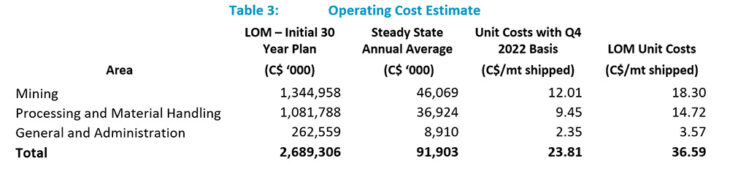

Operating costs for the Project have been estimated based on first principles build-ups, estimations of labor quantities and remuneration, productivity, and consumption assumptions. The operating cost estimate is as of the fourth quarter of 2022. Operating costs are divided into disciplines including mining, processing, general and administration, and port operations. SLR has assumed that the port would be owned and operated by a third party and accessible based on commercial terms. The operating cost estimate is presented in Table 3.

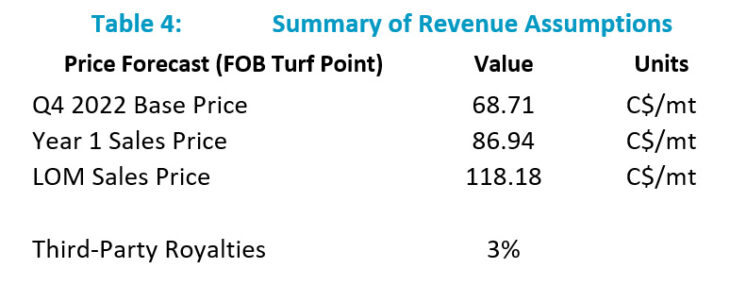

SLR has assumed a weighted average price of rock salt based on a market analysis review completed by a third party, as well as taking into consideration the shipping and logistics costs of getting the salt to destination ports. SLR’s revenue analysis is based on pricing FOB Turf Point and is based on the fourth quarter of 2022. The Project is subject to a royalty payable to Vulcan Minerals Inc., in the amount of 3% of net production revenue. A summary of revenue assumptions is presented in Table 4.

The resulting economics of the Project are presented in Table 5.

Upon completion of the PEA, Atlas intends to release a supporting NI 43-101 compliant report posted to SEDAR within 45 days of this news release. Other ongoing work toward Feasibility Study completion includes the following:

This news release describes an updated Mineral Resource estimate and a PEA plan and cash flow based upon geological, engineering, technical and cost inputs developed by SLR Consulting (Canada) Ltd. A National Instrument 43-101 Technical Report (NI 43-101) will be filed on SEDAR within 45 days. The technical information in this news release has been prepared in accordance with the Canadian regulatory requirements set out in NI 43-101 and reviewed and approved by EurGeol Dr. John G. Kelly, P.Geo., FIMMM, MIQ, David M. Robson, P.Eng., MBA, Lance Engelbrecht, P.Eng., Derek J. Riehm, M.A.Sc., P.Eng., and Graham G. Clow, P.Eng. each of whom is a “qualified person” under National Instrument 43-101 – Standards of Disclosure for Mineral Projects (“NI 43-101”).

The technical information in this news release has been prepared in accordance with the Canadian regulatory requirements set out in National Instrument 43-101 and reviewed on behalf of the company by Patrick J. Laracy, P.Geo., CEO of Atlas Salt and a qualified person.

Bringing the Power of SALT to Investors: Atlas Salt owns 100% of the Great Atlantic salt deposit strategically located in western Newfoundland in the middle of the robust eastern North America road salt market. The project features a large homogeneous high-grade resource located immediately next to a deep-water port. Atlas is also the largest shareholder in Triple Point Resources as it pursues the development of the Fischell’s Brook Salt Dome approximately 15 kilometers south of Great Atlantic in the heart of an emerging Clean Energy Hub.

Did you enjoy this article?