by Tina Olivero

Published on March 5th, 2015

7 Technologically Advanced Oil Rigs

Oil rigs have been advanced by state-of-the-art technology, including sophisticated navigation systems, software,dynamic positioning devices and improved designs. Here’s a snapshot of seven of the most technologically advanced oil rigs in the world that have wow factor.

1. The Atlantis Deepwater Oil Rig: Somewhat Like Plato’s City

Nestled in the Gulf of Mexico, the Atlantis deepwater oil rig is one of BPs most technologically advanced rigs. Its platform is the deepest moored floating oil and gas production facility on the globe. There are several attributes that make the Atlantis

unique. It has an integrated semi-submersible design with its production quarters platforms supported by a mobile offshore drilling unit. Its field development also implements a network of wet-tree subsea wells. This amazing deepwater oil rig had a production capacity of 180 million cubic feet of gas daily and 200,000 barrels of oil per day.

2. Sakhalin Oil Drilling Platform in Russia

According to UFS IC macroeconomic analyst Vasily Ukharsky, the Sakhalin oil platform, is one of the most technologically advanced drilling platforms in the world. One of its most impressive features is its ability to operate 24/7 in sub-Artic conditions. In addition, it has unprecedented operations with its seismic protection system to withstand a 9.0 earthquake and its ability to withstand an 18-meter tsunami.

3. Brutus: 165 Miles Southwest of Louisiana

Brutus is a tension-leg platform oil rig trussed to the sea floor by tendons. Its deck is 245 feet long and stands 40 feet high. Its modern deck has five modules,

including a well bay, living quarters, drilling, power and processing. Embracing green technology, this oil rig makes all of its own power and desalinates the sea

water for human drinking. Its expected production is 100,000 barrels of oil per day and 150 cubic million feet of gas daily.

4. Colorado Oil Rigs: Here Come the Robots

The Synergy Resources Corporation is taking gas and oil technology to a new level with robotic rigs to strike it rich in Colorado’s most copious fields. This rig is

automated with crew members using joysticks to move sections of pipe into and out of the ground. Computer monitors display all the info needed on the

pressure and depth inside wells. With robotics, this crew won’t be needing much sleep.

5. Norway’s Statoil: Straight out of “Waterworld”

Norway’s Statoil was the first full subsea rig and is located at its Tordis field in the North Sea. Its developed technology is increasingly autonomous and will be linked directly to the shore. The use of subsea technology makes it easier to install export pipeline, less costly to extract reserves and efficient to extract in deeper waters. Norway’s Statoil is one of the smart rigs of the future.

6. Petrobras’ Marlim Field: 4D Seismic Comes of Age

Located in the Campos basin off the shore of Brazil, this oil field is exemplary of how 4D seismic technology can be implemented for reservoir management decisions. Its benefits have been seen in applications to monitor fluid movement and identify undrained and drained portions of a reservoir. It merges predictive computer simulations of reservoir drainage in real acoustic images.

7. The World’s Biggest Jack-Up Rigs in the North Sea

The XLE rigs by Maersk Drilling in the North Sea have legs of 678 feet long and operate in water depths up to 492 feet. These rigs are innovation on a grand

scale. Its drill floor has a fully remote operate pipe handling system where all the basic operations like tripping and stand building can be conducted without crew members on the floor.

Technological innovation in oil rigs has equipped the industry with the advanced

equipment needed to increase production and meet rising demand. Plus, these new advanced technologies have made the production of oil more efficient, safe and environmentally friendly.

Did you enjoy this article?

Risk Reduction With Marine Institute Offshore Simulator

Risk Reduction With Marine Institute Offshore Simulator White Rose Extension

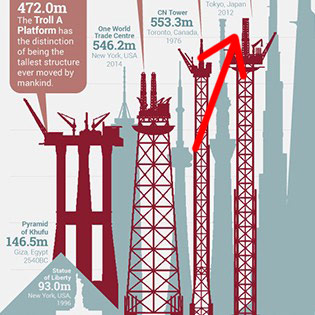

White Rose Extension How Tall are the World’s Largest Offshore Oil Structures?

How Tall are the World’s Largest Offshore Oil Structures? Atlantic XL - Big Name, Giant Vision

Atlantic XL - Big Name, Giant Vision These 4 Women of Distinction are Shaping the Offshore Industry

These 4 Women of Distinction are Shaping the Offshore Industry