by TheOGM

Published on June 9th, 2012

Mitigating Corporate Risk With a Real-Time View of Well Integrity

Well failures hit oil and gas operators hard, putting production, people and the environment at risk. Well integrity management systems provide an integrated source of critical data and real-time visibility of well integrity across the enterprise to ensure a robust approach to managing corporate risk and ensuring compliance.

Dr. Liane Smith (FREng), director and founder of Intetech, examines how well integrity management systems can turn large volumes of operating data into actionable business

intelligence to give users a 360° view of corporate risk.

Well integrity management is becoming a vital element in managing corporate risk for operators. Spills and leaks through loss of integrity can harm people, the environment and a firm’s reputation. In addition to the severe curtailment to production and the cost of shut-in, there is also the cost of restitution and remediation.

Given that the operational phase of a well life can last for 30 years or more, one of the biggest problems is managing the huge volume of operating data necessary to ensure an optimum safe condition is maintained for the whole design life. Many oil and gas operators continue to rely on handover documentation and a patchwork of bespoke production management databases and spreadsheets to manage this data, such as annulus pressure readings, valve and seal leak tests, and well logs.

Yet consolidating raw operating data using a well integrity management solution with smart functionality and single dashboard user interface provides a relatively low-cost but extremely powerful means of tracking the integrity of operating wells in real-time. Such systems allow users at every level to analyze and report on key performance indicators (KPIs) enterprise-wide, or instantly access more granular data at a per well per annulus level, apply exception reporting and traffic light warnings to highlight issues immediately and optimize repair and test schedules.

Indeed, taking a proactive approach to well integrity management is proven to reduce the risk of well failure and integrity-related shut-ins by up to 80 percent. It can

also extend safe operation beyond the original design life, a key challenge for those oil and gas operators having to deal with aging equipment and facilities.

An emerging discipline

As a sub-set of asset integrity management, well integrity management systems exist both at a documentation and software level, and combine key well operating and production data within a framework for decision-making, management processes and organizational structure.

Recently, an ISO committee began working on an international standard (ISO/NP 16530) to provide guidance on well integrity management during the operating phase—i.e., from the handover of construction phase to abandonment. This will assure compliance with a defined safe operating envelope including a wide range of parameters for temperature, pressure and fluid composition, and is designed to minimize the risk of an uncontrolled release of hydrocarbons or associated products.

The ISO standard will also set out a test criteria philosophy according to type of well and exposure of risk to people, environment, assets and reputation. Well types will be defined by location (onshore, offshore, subsea) and functionality (producer, injector, water disposal, etc.), together with corresponding safe operating envelopes, barrier elements and risk-based monitoring and maintenance plans.

Complying with such guidelines will present a major challenge for oil and gas operators, since the required information falls into a number of distinct categories and must be acquired from a wide range of sources. In most cases, these sources are today scattered across the enterprise. Without software to manage well integrity data, it can take as much as 70 percent of total project time just to assemble the necessary data for analysis during investigations concerning well integrity problems.

The cost of disparate data

Collecting operating well production data, chemical analysis of fluids, well logging data and annulus pressures is time-consuming and open to error through manual data transfer. The required information is often held in databases or file systems located in different departments. The results are silos of potentially critical information, making it difficult to review and identify problem wells, while it can take weeks of intensive effort to collate the necessary information for annual audit and management reporting.

Furthermore, the frequency with which information is collected varies significantly. Operational and production data might be collected several times a day, whereas leak testing of well barrier components is typically performed every six months. Well logging or other inspections may occur every few years. Regardless of frequency, operators need immediate access to the latest available data in each of these areas.

Sustained annulus pressure, for example, poses the greatest threat to well integrity, but if a build up of annulus pressure at a well is identified early on and remedial steps are taken in a timely manner, it is possible to return that well to a completely safe-operating condition long before the situation becomes critical. A shut-in or blowout can therefore be avoided by this proactive approach to well integrity management.

Pulling data silos together

Advanced well integrity management systems can interface to a wide range of third-party databases to collate the necessary information for analysis and identification of wells shifting outside critical safe operating limits, for the assessment of equipment reliability and well risk, and for real-time estimation of the corrosion in the well tubing. Data can also be acquired directly via tablet PCs in the field, entered manually, or via spreadsheet loader.

With operating well data consolidated within a single user interface, the addition of smart functionality enables operators to analyze the well condition automatically in real time and generate concise reports customized to their individual requirements. This ensures they have the specific “tools” needed to satisfy local regulations, proactively identify potential problems and plan test schedules and repairs. They can perform risk evaluation against complex criteria, for example, assessing the tubing condition based on varying production conditions or calculating maximum allowable annulus surface pressure (MAASP) values in real time.

Users can also generate and manage well handover documentation, track scaling issues and determine mean time to failure of equipment to establish risk-based inspection frequencies. But just as important is the ability to manage by exception, given the deluge of data faced by oil and gas operators today. With a system managing by exception and automatically identifying issues using a simple traffic light system, issuing email alerts and automatically risk-ranking wells that fail to meet safe operational limits; it is possible to establish effective control of well integrity.

Reducing cost and risk with real-time visibility

Although the risk of a blowout occurring during the operating phase of a well is much lower than that during the drilling phase, the risk to production posed by well shut-ins or abandonment and the fact an oil and gas firm typically operates hundreds or even thousands of wells simultaneously means that the level of corporate risk is no less significant.

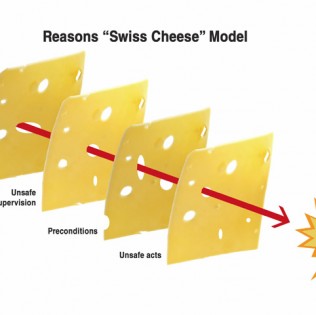

Many of the major incidents to have occurred in the oil and gas sector in recent history have been the result of a clash of routine activities. The risk level on one well, for example, may be compounded by the integrity issues on offset wells. This is easily visualized using a well integrity management system, which prevents the potential escalation of overall installation risk.

Accurate and real-time well integrity data ensures critical systems and equipment perform as expected, that production is optimized and that wells are operated in a way that maintains the optimum safe condition for their whole design life. The result is higher productivity and major cost savings for operators for a relatively low-cost software implementation that obtains maximum value from well integrity data. At the same time, presenting this information via a management dashboard provides senior executives and other users with a 360° view of well integrity at the individual well, field and company level.

With tolerance to environmental and reputational damage at an all-time low, oil and gas operators must ensure they have an effective oversight of every aspect of their business. A well integrity management system with dashboard and exception-reporting functionality enables operators to prove adherence to corporate governance policies and regulatory demands, ensure high integrity of operating wells and manage risk as part of a robust and auditable process.

Did you enjoy this article?

Accident Trajectory & Safety Culture

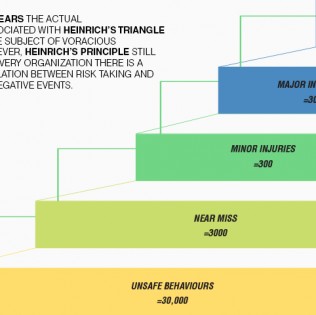

Accident Trajectory & Safety Culture Process Safety - The Heinrich Model of Behavior

Process Safety - The Heinrich Model of Behavior Online Safety Education – Part of the Technological Innovation Making Workplaces Safe

Online Safety Education – Part of the Technological Innovation Making Workplaces Safe Step Change

Step Change Top Tech Tools for the Safety Professionals

Top Tech Tools for the Safety Professionals.jpg)