Fire-resistant Workwear

Keeping your crew safe from burn injuries and fatalities is paramount to the success of any project. As peter clark of apparel solutions international, inc., In edmonton, ab, states, “effective safety programs should always aim at eliminating and engineering out the hazard or risk” within a susceptible work environment.

However, when it is not possible to eliminate the risk of a hydrocarbon flash fire or an electric-arc flash incident, then the hazard posed by “normal” workwear—by igniting or melting—must be engineered out. A difficult concept to comprehend is how, in most of the incidents, the clothing being worn can contribute to a greater degree of burn severity than would have been caused by just the incident itself.

“I know of numerous incidents with severe burn injuries and resultant fatalities in which we later determined if the workers had worn no clothing [at all], their injuries would have been less severe, and there would not have been any fatalities,” explains Clark.

With nudity on the jobsite an improbability, a better solution is to use workwear that is both flame resistant (FR) and arc rated (AR), and serves as personal protective equipment (PPE).

“This dual possibility of ‘workwear’ being either hazardous or protective is what makes FR/AR workwear unique in comparison to most other PPE, which includes hard hats, safety glasses, and boots.” says Clark, who published the FRW handbook years ago, explaining the role of workwear in determining burn severity. He used his knowledge gained both from his own personal experience, and that from many other survivors of industrial flash fires and explosions.

This concept has now become better understood and has been incorporated into the flash fire PPE workwear standards CAN/CGSB-155.20 and NFPA 2112, and also in the CSA Z462-12 “Workplace Electrical Safety Standard.” These workwear standards are described as follows:

4.3.7.3.11 Clothing Material Characteristics

Arc-rated clothing shall meet the requirements of this Clause and Clause 4.3.7.3.12.

Notes

(1) Arc-rated materials such as flame-retardant treated cotton, meta-aramid, para-aramid, and poly-benzimidazole (PBI) fibres provide thermal protection. These materials can ignite but will not continue to burn after the ignition source is removed. Arc-rated fabrics can reduce burn injuries during an arc flash exposure by providing a thermal barrier between the arc flash and the wearer.

(2) Non-arc-rated cotton, polyester-cotton blends, nylon, nylon-cotton blends, silk, rayon, and wool fabrics are flammable. Fabrics, zipper tapes, and findings made of these materials can ignite and continue to burn on the body, resulting in serious burn injuries.

(3) Rayon is a cellulose-based (wood pulp) synthetic fibre that is a flammable but non-melting material. Clothing consisting of fabrics, zipper tapes, and findings made from flammable synthetic materials that melt at temperatures below 315 °C (600°F), e.g., acetate, acrylic, nylon, polyester, polyethylene, polypropylene, and spandex shall not be used alone or in blends.

Note: These materials melt as a result of arc flash exposure conditions, form intimate contact with the skin, and aggravate the burn injury.

Clark says that similar to other PPE, Apparel Solutions’ workwear must meet the appropriate FR/AR PPE workwear standards, provide the required level of protection, and often meet other PPE standards such as high visibility. The good news is that the ability for FR/AR workwear to hold up to these standards has been proven, as is their ability to meet other workwear requirements, such as being “breathable” or waterproof in hot or wet environments.

According to Clark, “Our North American FR and AR PPE workwear standards are quite different from other international standards, and in my belief much superior.”

Nonetheless, training is crucial to ensure workers are not wearing underclothing that can contribute to burn severity by melting. Due diligence must also be performed to ensure that FR and AR meet the PPE standards claimed, provide the necessary protection, and are not counterfeit, while also meeting the full balance of workwear requirements.

Apparel Solutions International manufactures third-party certified PPE apparel, distributed through distributors in the Maritimes, and can also be contacted directly for help in training or in developing new PPE apparel solutions.

Did you enjoy this article?

Project Risk Reduction - Expecting The Unexpected

Project Risk Reduction - Expecting The Unexpected Safety Goes Online

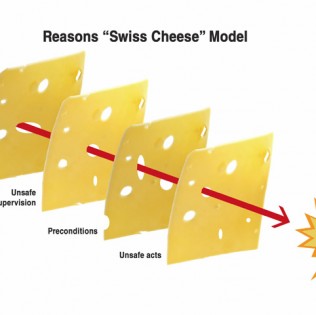

Safety Goes Online Accident Trajectory & Safety Culture

Accident Trajectory & Safety Culture Offshore Safety: Maersk’s Global Standards

Offshore Safety: Maersk’s Global Standards A Grounded Approach Expands Offshore Operations

A Grounded Approach Expands Offshore Operations