WorleyParsons Exposé

Published on October 20th, 2014

Step Change

With a renewed focus on contractor safety, WorleyParsons’ “Step Change” program takes a significant leap in realizing their vision of zero harm to people, assets and the environment.

What is “Step Change?”

After analyzing past safety performance, WorleyParsons found that the majority of field incidents did not involve their own employees. Rather, their performance data indicated that most incidents, including high-potential incidents, were a result of work performed by contractors and sub-contractors. With invaluable primary data revealing gaps in safety performance, the company found an opportunity to focus on how contractors and subcontractors were selected and managed throughout a project’s lifecycle. This renewed focus resulted in a comprehensive suite of practices known as “Step Change.”

Step Change is based on the same philosophy as WorleyParsons’ enterprise management framework: OneWay™, which integrates safety into all aspects of the business operations from planning and engineering to field construction. Similarly, the Step Change program integrates safety into all aspects of the construction management process, with a focus on the project specific decisions and actions carried out by the Construction Management Team (CMT).

“At WorleyParsons, our Step Change program is continuously utilized by our site based teams to work towards our goal of zero harm,” says Jeff Lace, Construction Director. “Our Step Change program allows us to identify and implement on the fly, changes in daily operations to ensure that every day begins with a zero harm goal in mind.”

Reaching Zero Harm Via Step Change

No two projects are alike. The risks associated with each project are ever-changing and dependent on its complexity. Step Change allows for specific project considerations to be made, which link back to overall safety expectations.

WorleyParsons doesn’t just market safety capabilities; they develop programs, set expectations, and track performance to ensure they are delivering what they promise to customers – successful project execution. “To us, zero harm is more than a slogan; it is a journey towards our vision that forms a key part of our core values within the organization,” says Chris Letkeman, HSE Director. “We set improved safety performance targets annually that bring us closer to achieving our vision of zero harm. This journey is supported by our continuous improvement initiatives, such as the Step Change program, and to ensure safe and successful project completion”.

The implementation of the Step Change program has allowed WorleyParsons to reinforce their continuous improvement philosophy towards zero harm. “When it comes to our people, our contractors and delivering to our customers, zero-harm is the top goal that we set for ourselves,” proudly states Chris Letkeman.

Did you enjoy this article?

Online Safety Education – Part of the Technological Innovation Making Workplaces Safe

Online Safety Education – Part of the Technological Innovation Making Workplaces Safe Accident Trajectory & Safety Culture

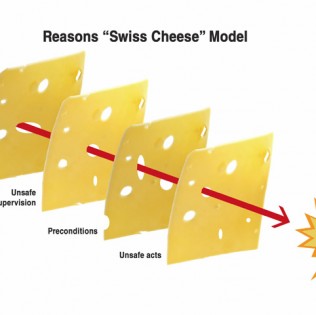

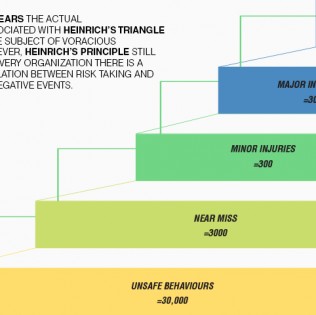

Accident Trajectory & Safety Culture Process Safety - The Heinrich Model of Behavior

Process Safety - The Heinrich Model of Behavior Top Tech Tools for the Safety Professionals

Top Tech Tools for the Safety Professionals May You Never Hear These Words—Ditching, Ditching, Ditching.

May You Never Hear These Words—Ditching, Ditching, Ditching..jpg)